machine tool retrofitting

Retrofitting

Reliability and competence: the customer comes first

Machine Tool Retrofitting and CNC Retrofit Services

CO.MA.F offers machine tool retrofitting services to help manufacturers restore the full value and performance of their existing equipment. Machine tool retrofitting improves efficiency by recovering original performance levels, reducing frequent repair costs, and significantly extending machine lifespan.

Our expert technicians handle every phase of the process: inspection, repair, component replacement, and final testing. Whether your machines need mechanical updates or control system upgrades, we provide comprehensive solutions tailored to your production needs.

We also deliver CNC retrofit services for older systems, replacing outdated controls with modern CNC platforms to increase precision, automation, and operational speed.

Contact us with confidence or visit our Facebook page to learn more about our services and products!

Follow us on Linkedin!

Machine Tool Retrofitting: what we offer

RECONDITIONED MACHINES

TECHNICIANS

ASSISTANCE CENTRES

Our projects

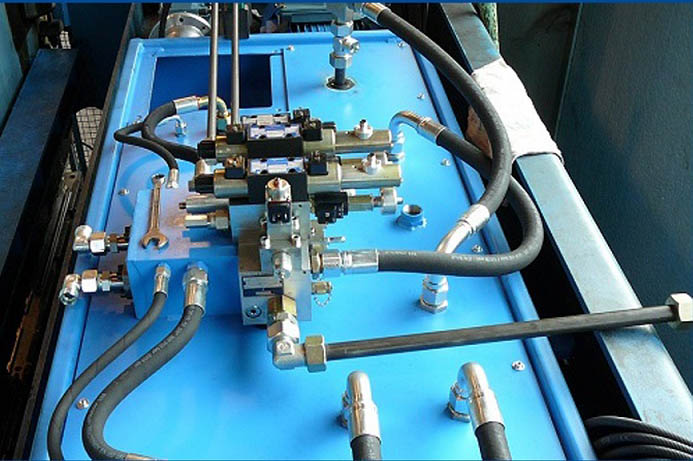

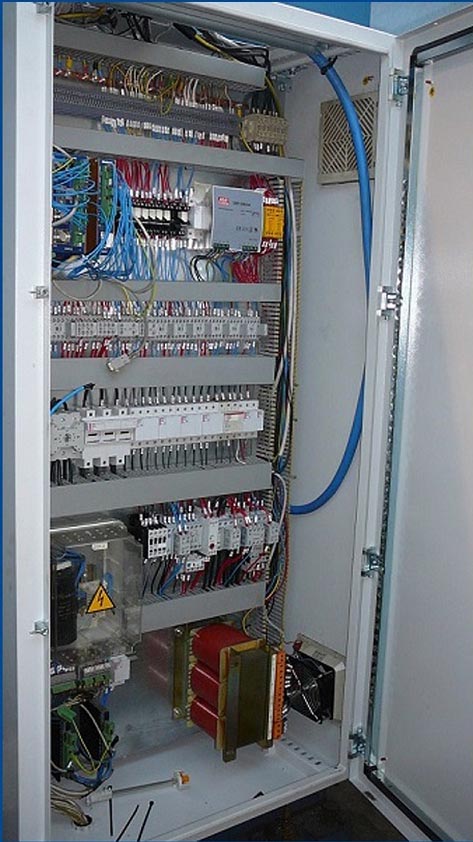

Before

After

Before

After

Before

After

Before

After